Faster, smoother, better, stronger (at high speeds): bipolar parallel stepper wiring

Quick tip: if you're looking for higher maximum speeds with your bipolar stepper motors, try wiring the windings in parallel instead of series. According to a short National Instruments article, it can increase torque at higher speeds, reducing the chance that the motor will stall during fast rapids.

Header photo by Yung Chang

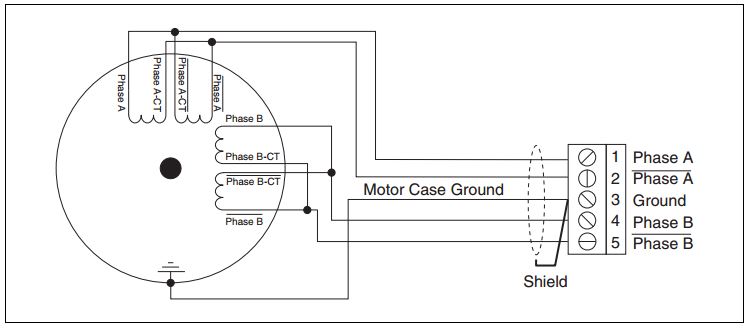

Credit: National Instruments

There is a caveat though: you'll need a higher current to get the required torque. That's not a problem for the M542T stepper drivers I'm using; my motors are rated for 3 amps in bipolar parallel which the driver can easily handle.

I've managed to reliably get 150mm/sec (9m/min!) rapids out of my gantry router using 10mm/rev ballscrews. Peck drilling is even more fun to watch now.